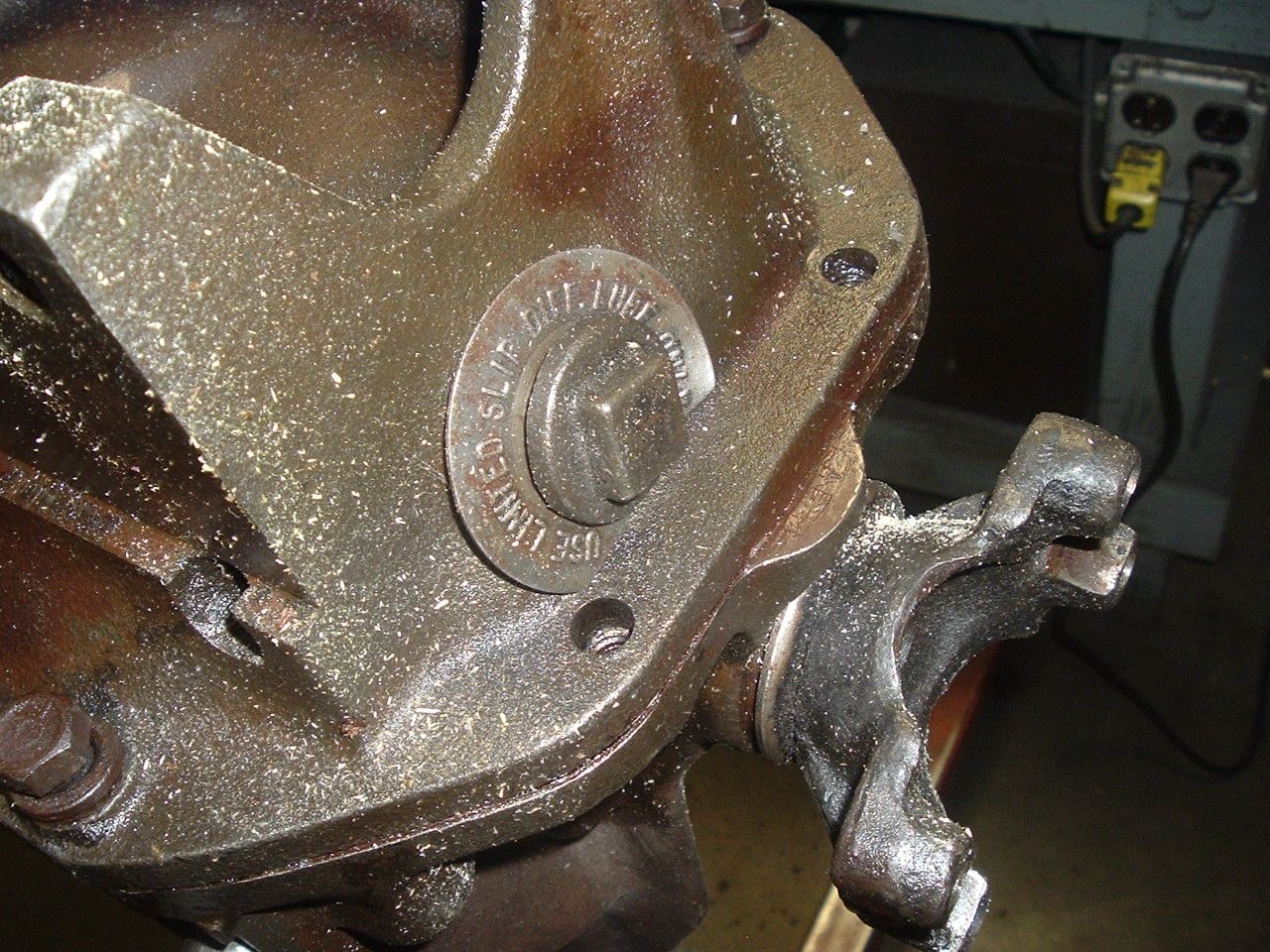

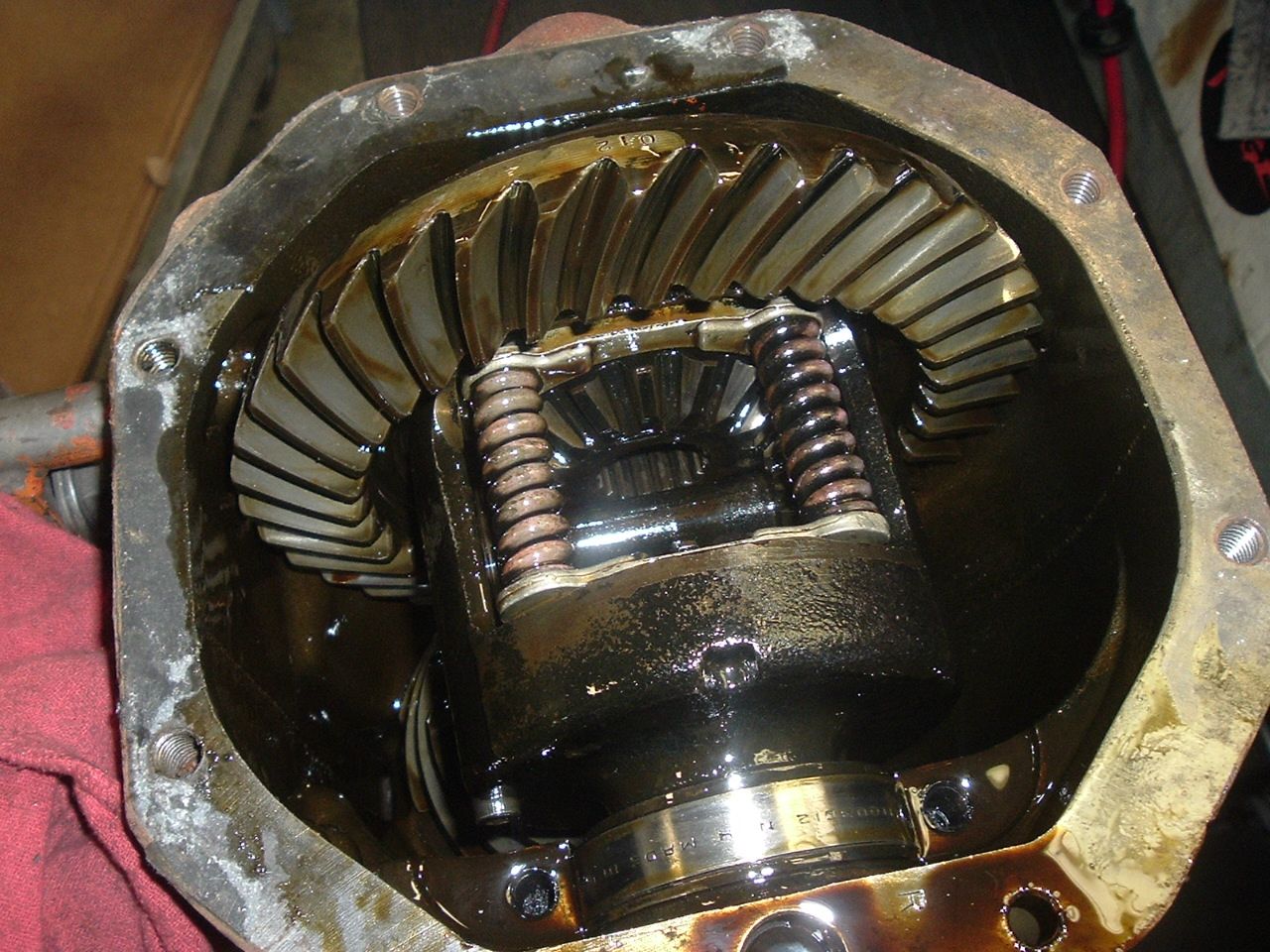

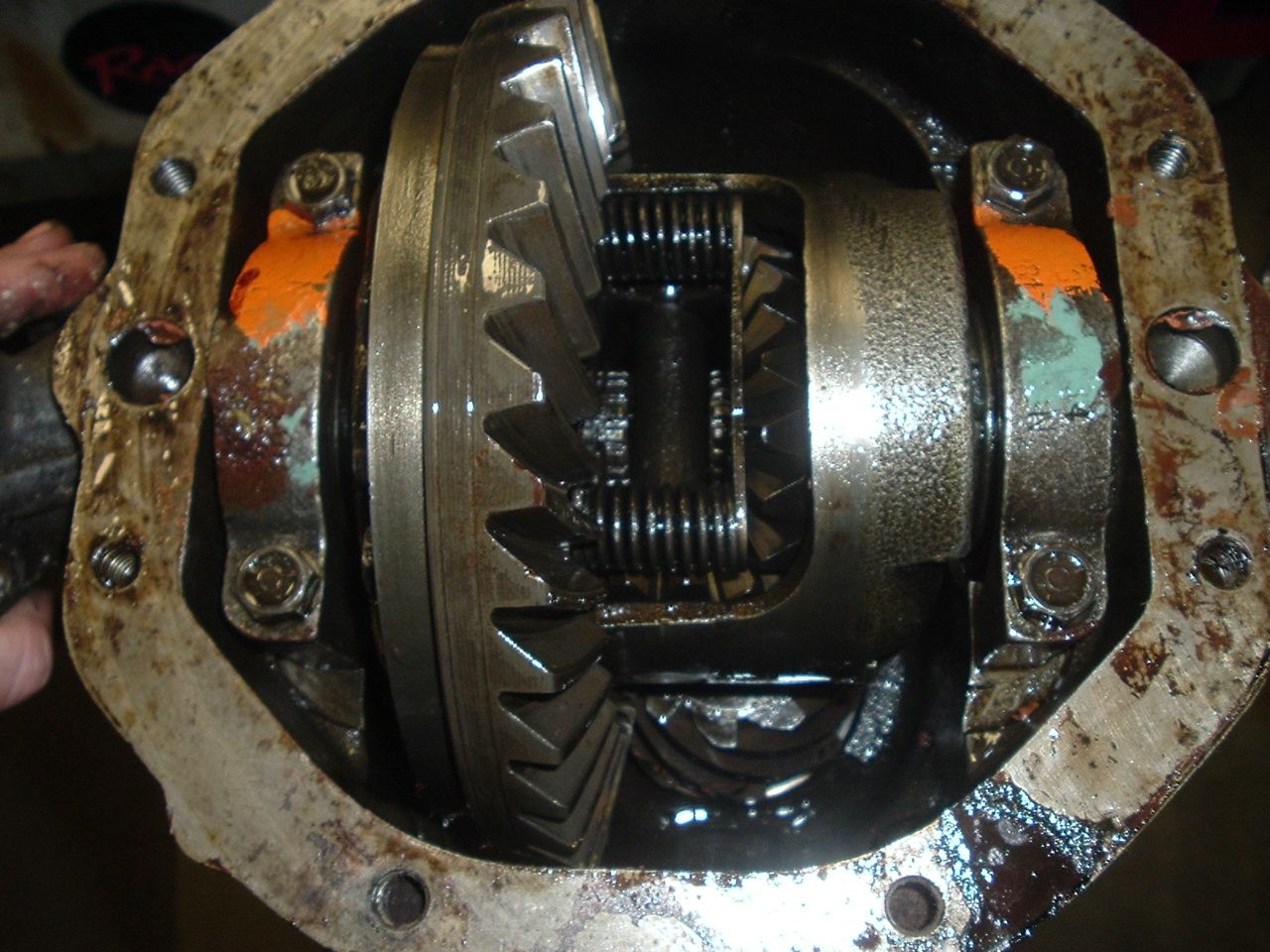

I am looking for advice on my damaged differential. I just finished a complete restoration on my 64 conv. I literally replaced or rebuilt EVERY nut and bolt on the car EXCEPT the differential. Well, as they say, you are only as good as your weakest link. I have put about 650 miles on the car and as I let the clutch out to pull away at a stoplight, I heard/felt a loud clank/clunk....the car lurched forward about a foot with a screech and stopped. I immediately shut it down. After checking underneath and not seeing anything unusual, I started it back up and tried to move it, but no dice. I shut it off and discovered it would not roll forward at all, but it would roll backwards (by hand pushing the car in rush hour no less). I had it towed and I removed the drive shaft and realized the pinion flange was dangling loose similar to a broken wrist. I am not yet sure if the pinion flange is the only problem or did I break the ring and pinion or ?

My question is...what to do? Would you advise pulling the rear end/pumpkin and completely disassembling it and then fix only what appears to be the problem OR disassembling it and having it COMPLETELY rebuilt by a professional?

My common sense tells me to have it completely rebuilt by a pro (as long as I'm in there). If this is the best option, then who do you all recommend I send it out to that will do it properly the first time (ring and pinion, gear set up so there is no "noise", clutch pack for posi-traction etc, side yokes). I live near St. Louis, MO. The rear end is the original for my car with all correct numbers etc. It is a 3:36 four speed.

All thoughts are greatly appreciated!

Thanks in advance.

Tim

My question is...what to do? Would you advise pulling the rear end/pumpkin and completely disassembling it and then fix only what appears to be the problem OR disassembling it and having it COMPLETELY rebuilt by a professional?

My common sense tells me to have it completely rebuilt by a pro (as long as I'm in there). If this is the best option, then who do you all recommend I send it out to that will do it properly the first time (ring and pinion, gear set up so there is no "noise", clutch pack for posi-traction etc, side yokes). I live near St. Louis, MO. The rear end is the original for my car with all correct numbers etc. It is a 3:36 four speed.

All thoughts are greatly appreciated!

Thanks in advance.

Tim

Comment