I get a couple of calls a week from guys looking for GM quality rag joints. I only have one of each left and will hold on to them, does anyone know of a quality rag joint sold today? I sure don't, the ones I see are cheap imported ones with the D flat off 180*, rag material too pliable, no grounding, cheap bolts, etc.

Rag Joints

Collapse

X

-

Re: Rag Joints

Gary-----I get a couple of calls a week from guys looking for GM quality rag joints. I only have one of each left and will hold on to them, does anyone know of a quality rag joint sold today? I sure don't, the ones I see are cheap imported ones with the D flat off 180*, rag material too pliable, no grounding, cheap bolts, etc.

I know of NO current source for a quality steering coupling, either the 67-E69 or L69-82. These now fall into the same category as 63-82 motor mounts. The best ones on the market are decidedly inferior.In Appreciation of John Hinckley- Top

-

Re: Rag Joints

Hi Joe & Happy New Year.

I agree it's a pretty poor selection from what I saw from the pictures guys posted. I know one of my last conversations with Tom Riena well over a year ago was about rag joints, he used to make one as good as GM did but he told me he couldn't get the material anymore and stopped making them. I know he supplied a lot of the vendors with rag joints for years. There are probably still some NOS GM's out there but those that find them will be paying well over $200 I suspect for them now.- Top

Comment

-

Re: Rag Joints

Gary-----

I saw this coming years ago and "stocked up" on both the 67-E69 and L69-82 couplings [none for sale]. I've got enough so that no matter which configuration steering box I use I'll have enough couplings if I live to be about 400 years old. Currently, I have the L69 steering box in the car but it was originally built with the E69 box (car built mid-September, 1969).In Appreciation of John Hinckley- Top

Comment

-

Re: Rag Joints

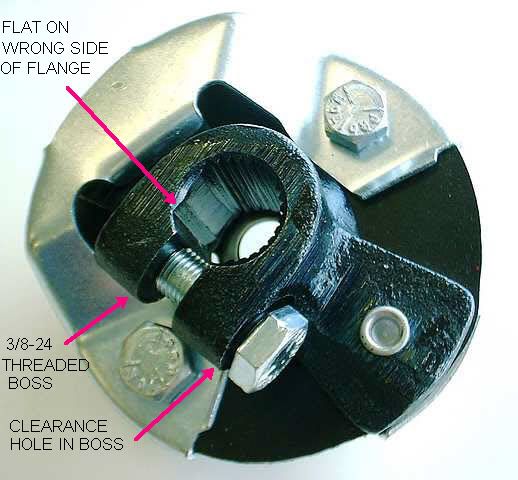

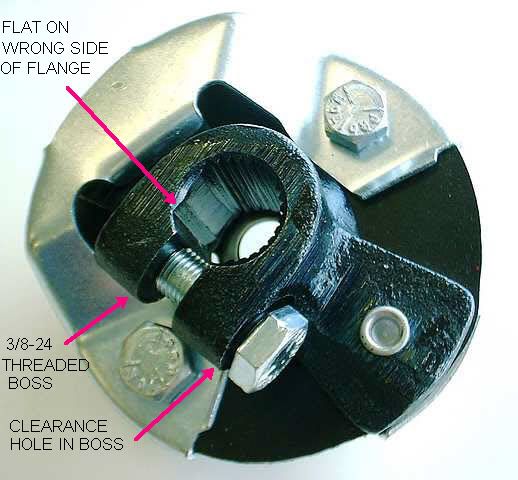

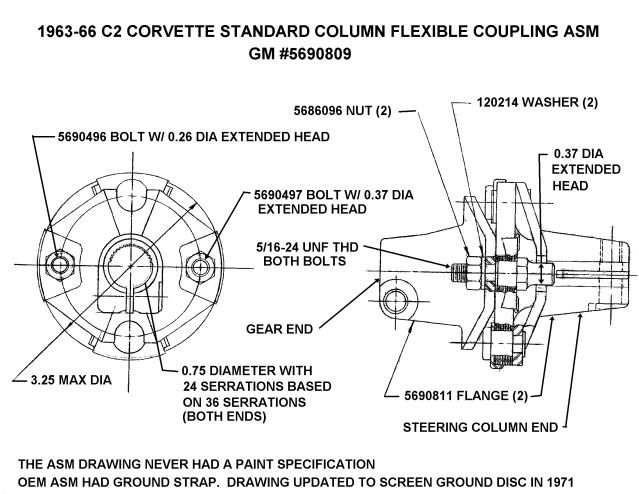

Here is a picture of the incorrectly machined flex coupling assembly.

The flat should be located on the bolt head side not the threaded boss side.

I discovered this problem a couple years ago. Seems like it still haunts us today. The flat being machined on the incorrect side of the bowtie flange will result in your steering wheel ending upside down. You can fairly easily make this offshore manufactured part work by interchanging the 3/8 and 5/16 attaching bolts.

Let me make one more comment on horn grounding. The flexible coupling assembly should have a metal screen or a stamped brass ground strap to reliably carry horn grounding current from the steering shaft down into the steering gear and into the frame and back to the battery. However, steering columns in the 1960s through 1980 had metal die cast housings or stampings that may have carried the grounding current into the steering column jacket, into the column mounting, and eventually back to the battery. So the early columns may have had multiple ways for the horn current to reach the vehicle ground. Now when the steering column head was converted to plastic in 1981, that should have eliminated the alternate grounding paths.

You should always recheck your horn function when you replace your flexible coupling. I can just imagine someone who (months after replacing the flex coupling) tries to blow his horn and now is left with trying to figure out what went wrong!

Jim- Top

Comment

-

Re: Rag Joints

Jim------Here is a picture of the incorrectly machined flex coupling assembly.

The flat should be located on the bolt head side not the threaded boss side.

I discovered this problem a couple years ago. Seems like it still haunts us today. The flat being machined on the incorrect side of the bowtie flange will result in your steering wheel ending upside down. You can fairly easily make this offshore manufactured part work by interchanging the 3/8 and 5/16 attaching bolts.

Let me make one more comment on horn grounding. The flexible coupling assembly should have a metal screen or a stamped brass ground strap to reliably carry horn grounding current from the steering shaft down into the steering gear and into the frame and back to the battery. However, steering columns in the 1960s through 1980 had metal die cast housings or stampings that may have carried the grounding current into the steering column jacket, into the column mounting, and eventually back to the battery. So the early columns may have had multiple ways for the horn current to reach the vehicle ground. Now when the steering column head was converted to plastic in 1981, that should have eliminated the alternate grounding paths.

You should always recheck your horn function when you replace your flexible coupling. I can just imagine someone who (months after replacing the flex coupling) tries to blow his horn and now is left with trying to figure out what went wrong!

Jim

This is also a rather crude appearing coupling. I'll bet if we could see the manufacturing facility it came out of it would be scary. Unfortunately, this sort of coupling is pretty much "what's out there" these days for 67-82 Corvettes.In Appreciation of John Hinckley- Top

Comment

-

Re: Rag Joints

Timely post as I picked up some parts yesterday and a rag joint was in the box. It appears to be well made but it has no machined flat as shown in the parvious post by Jim.

Is this one worth keeping......?

Tom

PC301903.jpgPC301904.jpgPC301905.jpgPC301906.jpg1958, 283/245, White/red - Top Flight, October 2016

1960, Black/black, 283/230 4sp

1966, Black/Red, 327/350 4sp w/AC

1967, 427/390, 4sp, Goodwood Green, Coupe

1971 LS5, 4sp, coupe, Bridgehampton Blue

2007 Z06, Lemans Blue

Newsletter Editor, Delaware Valley Chapter- Top

Comment

-

Re: Rag Joints

Tom-----Timely post as I picked up some parts yesterday and a rag joint was in the box. It appears to be well made but it has no machined flat as shown in the parvious post by Jim.

Is this one worth keeping......?

Tom

[ATTACH=CONFIG]43698[/ATTACH][ATTACH=CONFIG]43699[/ATTACH][ATTACH=CONFIG]43700[/ATTACH][ATTACH=CONFIG]43701[/ATTACH]

This looks like a 1963-66 Corvette non-tele coupling. It also appears to be a GM piece, GM #5690809.In Appreciation of John Hinckley- Top

Comment

-

Re: Rag Joints

Thanks Joe. Makes sense as the parts I got yesterday were from a shop that had done some work on a 67 years back. Maybe they bought this one and realized it was not correct for a 67 and just shelved it which is exactly what I'm going to do. I have my sights set on getting a 66 in the next few years so I may have a need for it.

Tom1958, 283/245, White/red - Top Flight, October 2016

1960, Black/black, 283/230 4sp

1966, Black/Red, 327/350 4sp w/AC

1967, 427/390, 4sp, Goodwood Green, Coupe

1971 LS5, 4sp, coupe, Bridgehampton Blue

2007 Z06, Lemans Blue

Newsletter Editor, Delaware Valley Chapter- Top

Comment

-

Re: Rag Joints

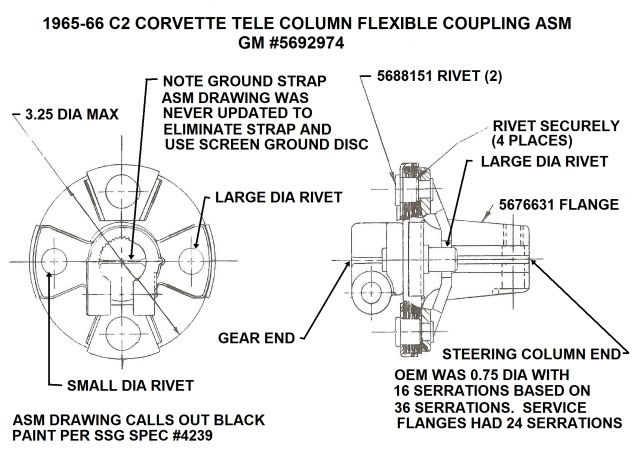

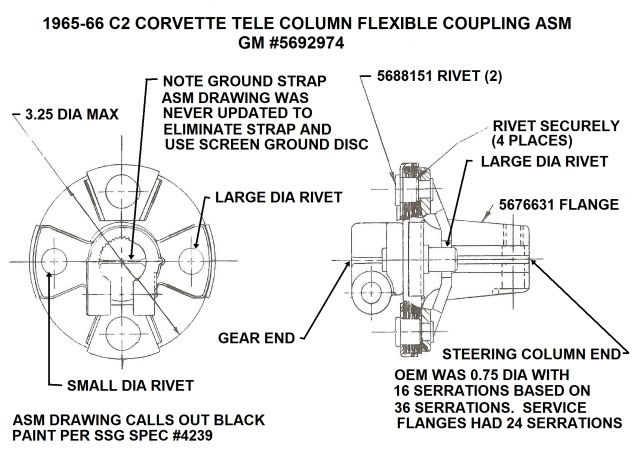

Your part appears to be a service part, 5692974 telescoping steering column flexible coupling assembly. This was the flexible coupling for the 1965-66 Corvette with telescoping steering column. I say service part because there is red paint on the coupling disc which would indicate that there is a metal screen molded into the face of the disc. The metal screen was introduced throughout GM starting around 1971. The original flex coupling would have had a brass grounding strap that you could see by looking down the throat of the assembly.

The actual service assembly drawing shows two different size rivets whereas your picture seems to show equal size rivets. From a functional standpoint the size of the rivets would not be important as long as the clearance between the rivets and the cutouts in the 5676631 flange were equal.

I would say that you have a rare Corvette service part.

Jim- Top

Comment

-

Re: Rag Joints

Joe,

Thank you for the detailed info. As you pointed out, both rivets are the same diameter and upon close inspection, the top disc does have a metal mesh embedded in it.

Gary, sorry to somewhat hijack your thread..................

Happy New Year

Tom1958, 283/245, White/red - Top Flight, October 2016

1960, Black/black, 283/230 4sp

1966, Black/Red, 327/350 4sp w/AC

1967, 427/390, 4sp, Goodwood Green, Coupe

1971 LS5, 4sp, coupe, Bridgehampton Blue

2007 Z06, Lemans Blue

Newsletter Editor, Delaware Valley Chapter- Top

Comment

-

Re: Rag Joints

Your part appears to be a service part, 5692974 telescoping steering column flexible coupling assembly. This was the flexible coupling for the 1965-66 Corvette with telescoping steering column. I say service part because there is red paint on the coupling disc which would indicate that there is a metal screen molded into the face of the disc. The metal screen was introduced throughout GM starting around 1971. The original flex coupling would have had a brass grounding strap that you could see by looking down the throat of the assembly.

The actual service assembly drawing shows two different size rivets whereas your picture seems to show equal size rivets. From a functional standpoint the size of the rivets would not be important as long as the clearance between the rivets and the cutouts in the 5676631 flange were equal.

I would say that you have a rare Corvette service part.

Jim

Jim-----

Yes, I was incorrect on the part number and non-tele application. The non-tele coupler has flange "extensions" on both sides.In Appreciation of John Hinckley- Top

Comment

-

Re: Rag Joints

I'd like to reopen this to ask a question. Have read many posts and the answer may be there but I haven't see it yet.

In the drawing above the note on the splines say 24 teeth of 36. In the pics below I count 16 full teeth and then either partials or none. Is this coupler worn out or is this fairly normal? Are there enough teeth here to clamp and hold as designed?

Thanks.- Top

Comment

Comment